Features:

- Compact and light off-line bypass oil cleaners.

- Effectively removes all the particles that are usually very difficult to remove with conventional filters, and performs a total cleaning of the oil by removing solid particles, absorbing water and eliminating sludge and other oil oxidation residues.

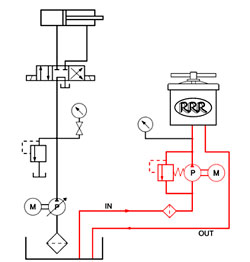

- Built around a very compact power pack, they can easily be connected to the oil reservoir.

- The standard version comes fully equipped with a metal suction strainer and a Moeller on/off switch box with thermo-protection. All units have a mounting bracket for quick installation and a pressure gauge to check the element contamination level.

- All SE off-line oil cleaners are fitted with M-series 2μabsolute filter elements (beta ratio ß3 >400).

- Standard units are suitable for systems with an oil tank capacity up to 600 litres.

- Low running cost, easy installation & maintenance.

- Also available for water glycol fluids with coated housing and WG element.

Benefits:

- Prevents trouble to the hydraulic equipments.

- Improves machine reliability and productivity.

- Longer life of all hydraulic components, pumps, servo-valves and other equipment.

- Extends oil life by up to 40.000 hrs.

- Very important reduction of oil consumption and the resulting waste oil.

- Discharges the full flow filters and extends their life.

- Important reduction of maintenance costs.

Typical applications:

- Injection moulding machines

- Die-casting machines, metal working machines, like bending-, cutting-, punching machines.

- All hydraulic systems with continuous pressure and fitted with proportional or servo-valves, and other high-tech hydraulic equipment.

Technical specification

|

Model |

Article nr. | Motor | Flow rate ℓ/min | Thread BSPT | Dimension mm | Weight (Dry) | Tank capacity | ||||||

| 200V | 100V | Power(W) Cycle(Hz) | 50Hz | 60Hz | IN | OUT | W | L | H | kg | Liter | ||

| SE30N-YT | 13410 | 13440 | 90 | 50/60 | 1.2 | 1.4 | 3/8 | 3/8 | 256 | 277 | 399 | 11.5 | >300 |

| SE50N-YT | 13510 | 13540 | 90 | 50/60 | 1.8 | 2.2 | 3/8 | 3/8 | 262 | 277 | 405 | 12.0 | >450 |

| SE100N-YT | 13620 | 13640 | 90 | 50/60 | 2.3 | 2.8 | 3/8 | 3/8 | 282 | 283 | 420 | 14.0 | >600 |

| SE100NW-YT | 13700 | 13740 | 90 | 50/60 | 1.8 | 2.2 | 3/8 | 3/8 | 282 | 283 | 420 | 14.0 | >300 |

| SS100N-YT | 14905 | 14915 | 180 | 50/60 | 4.1 | 4.9 | 3/8 | 3/8 | 282 | 283 | 420 | 15.5 | |

| SS200N-YT | 14200 | 14100 | 180 | 50/60 | 4.1 | 4.9 | 1/2 | 1/2 | 418 | 330 | 667 | 25.0 | >1,200 |

| SS100NW-YT | 14790 | 14795 | 180 | 50/60 | 2.7 | 3.2 | 3/8 | 3/8 | 282 | 283 | 420 | 15.5 | |

| SS100N-2R-YT | 14920 | 14930 | 180 | 50/60 | 4.1 | 4.9 | 1/2 | 1/2 | 365 | 542 | 400 | 23.0 | >1,200 |

| SS200NW-YT | 14400 | 14300 | 180 | 50/60 | 4.1 | 4.9 | 1/2 | 1/2 | 418 | 330 | 667 | 25.0 | |

| Model | Element type |

| SE30N-YT | (E30(20270) • M30(20230) • X30(25250)) |

| SE50N-YT | (E50(20370) • M50(20330) • X50(25350)) |

| SE100N-YT | (E100(20470) • M100(20430) • X100(25450) • D100(20000) • WE100(20450/Only Water absorber |

| SS100N-YT | |

| SS100N-2R-YT | |

| SS200N-YT | |

| SE100NW-YT | (WG100(25470)• DWG100(25480/Only Water glycol)) |

| SS100NW-YT | |

| SS200NW-YT |

Oil cleaner model selection chart for hydraulic

| Model | iter300 | Lit450 | Lit600 | Lit1200 | Lit300 | Lit600 |

| SE30N-YT |

√ |

|||||

| SE50N-YT |

√ |

|||||

| SE100N-YT |

√ |

|||||

| SE100NW-YT |

√ |

|||||

| SS100N-YT | Please contact your distributor for model details | |||||

| SS200N-YT |

√ |

|||||

| SS100NW-YT | Please contact your distributor for model details | |||||

| SS100N-2RYT |

√ |

|||||

| SS200NW-YT |

√ |

|||||

* Water glycol model : SE100NW-YT·SS100NW-YT·SS200NW-YT

* All circumstance should be considered before selecting a suitable oil cleaner and flow rate.

Please consult with your distributor for model detail.